Construction is a heavily-regulated industry – and for good reason. According to the National Safety Council (NSC), construction is the most dangerous industry in terms of the number of workplace deaths. Construction industry standards exist to protect workers. Safety compliance can help employers keep workers safe, maintain smooth operations, and avoid fines.

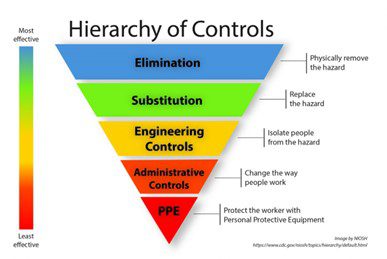

Increase Construction Safety Using the Hierarchy of Controls

According to the U.S. Bureau of Labor Statistics (BLS), nearly one in five of the workplace deaths that occurred in 2021 were in the construction industry.

The first step in avoiding and mitigating injuries and illness involves understanding the Hierarchy of Controls. According to the National Institute for Occupational Safety and Health (NIOSH), the Hierarchy of Controls includes five levels of actions that organizations should take to reduce or remove hazards to workers: elimination, substitution, engineering controls, administrative controls, and personal protective equipment. The order of the actions is based on general effectiveness, with the elimination of hazards being the most effective and personal protective equipment being the least effective (but still important).

For example, let’s say the hazard in question is a toxic chemical. Physically removing the chemical is the safest option, but if the chemical is essential to operations, that might not be possible. Other options include substituting the chemical with something safer, introducing engineering controls (such as ventilation), and implementing administrative controls (such as worker training). Finally, the workers can be given personal protective equipment, such as masks and gloves. Note that many of these controls can be used in conjunction with each other.

Construction is a heavily-regulated industry – and for good reason. According to the National Safety Council (NSC), construction is the most dangerous industry in terms of the number of workplace deaths. Construction industry standards exist to protect workers. Safety compliance can help employers keep workers safe, maintain smooth operations, and avoid fines.

Use Tools for Risk Assessment in Construction

Before implementing business safety measures, you must know which risks exist. Therefore, it’s important that construction leaders conduct thorough construction risk assessments.

Although the hazards can vary from work site to work site, many risks are common throughout the construction industry. OSHA says serious construction hazards include falling from rooftops, unguarded machinery, being struck by heavy construction equipment, electrocutions, silica dust, and asbestos. Your risk assessment should include (but not be limited to) these risks. As a starting point, OSHA offers a Hazard Identification Training Tool that gamifies hazard identification and helps raise awareness. You can access the interactive, web-based tool here.

The Department of Labor recommends a six-step hazard identification process:

- Collect existing information about workplace hazards

- Inspect the workplace for safety hazards

- Identify health hazards

- Conduct incident investigations

- Identify hazards associated with emergency and nonroutine situations

- Characterize the nature of identified hazards, identify interim control measures, and prioritize the hazards for control

Implement Controls, Including OSHA Standards

Many construction hazards can be avoided or mitigated using engineering and administrative controls. OSHA has developed numerous construction industry standards with these goals in mind.

Workers may be at risk when construction sites do not comply with these standards, and employers may face fines. The risk of fines may be increasing; Business Insurance warns that OSHA enforcement has become more aggressive, with a 20% increase in OSHA inspectors under the Biden administration.

Every year, OSHA releases the top 10 most frequently cited standards. According to Safety + Health Magazine, the most cited construction violations for 2022 were:

- Fall Protection – General Requirement Standard 1926.501: 5,980 violations

- Hazard Communication Standard 1910.1200: 2,682 violations

- Ladders Standard 1926.1053: 2,471 violations

- Respiratory Protection Standard 1910.134: 2,430 violations

- Scaffolding Standard 1926.451: 2,285 violations

- Lockout/Tagout Standard 1910.147: 2,175 violations

- Powered Industrial Trucks Standard 1910.178: 1,922 violations

- Fall Protection – Training Requirements Standard 1926.503: 1,778 violations

- Personal Protective and Lifesaving Equipment – Eye and Face Protection Standard 1926.102: 1,582 violations

- Machine Guarding Standard 1910.212: 1,488 violations

Use the OHSA Compliance Quick Start Process

OSHA recommends a seven-step process:

- Step 1: Learn the OSHA requirements related to leading construction site hazards. These include standards related to falls, stairways and ladders, scaffolding, electrical hazards, trenching and excavation, motor vehicle safety, and highway work zones.

- Step 2: Learn other OSHA requirements that may apply to your site. Common issues include hazard communication, hand and power tools, silica, concrete and masonry products, cranes, derricks, hoists, elevators, conveyors, welding, cutting, brazing, confined spaces, residential construction, steel erection, and fire safety.

- Step 3: Survey your workplace for additional hazards. The lists in steps 1 and 2 are not exhaustive – your job site may have additional hazards. You can use OSHA tools and resources to identify them.

- Step 4: Develop a job site safety and health program. OSHA requires construction employers to have accident prevention programs that include frequent and regular inspections of the worksite.

- Step 5: Train your employees. Safety training is critical. Without it, construction workers won’t know how to follow the safety protocols – or even know the safety protocols.

- Step 6: Manage recordkeeping, reporting, and posting requirements. OSHA requires most construction employers to keep records of workplace injuries and illnesses. Additionally, all employers must report fatalities and severe injuries. There are also requirements for OSHA posters.

- Step 7: Find additional compliance assistance information. Compliance with OSHA’s requirements for construction sites requires many elements. Bear in mind that standards may change in response to new hazards or awareness. OSHA has additional compliance assistance information to help construction employers.

Invest in Personal Protective Equipment

Personal protective equipment is key to workplace safety and construction work management. OSHA has several standards related to personal protective equipment and the construction industry, including standard 1926.8, which states that the employer is responsible for requiring the wearing of appropriate personal protective equipment.

Providing personal protective equipment is not enough. Employers also need to train workers on how to use the equipment and verify that equipment is actually being used consistently and correctly. Additionally, employers need to provide PPE that fits both men and women, workers of different sizes, and workers with disabilities or physical differences. For example, a fall harness designed for an average-sized man might not fit a woman properly, and the CDC warns that poorly fitted fall protection harnesses are ineffective and can actually cause fall injuries.

Seek Guidance from a Specialized Construction Insurance Partner

When it comes to construction injuries, prevention is always the best course of action. However, given the high-hazard nature of construction, some injuries may occur despite adequate safety measures, making insurance critical.

For the smartest coverage design, work with an insurance broker who specializes in the insurance industry. They can help you identify the types of coverage you need and help you avoid paying for coverage you’ll never use.

Your broker may recommend general liability, professional liability, property, workers’ compensation, environmental and pollution coverage, cyber, commercial auto, and builder’s risk policies. Every construction company’s needs are a little different, and your policy should be customized to address the unique exposures of your business.

How Safety Sharpens Your Competitive Edge

Although construction safety programs often focus on OSHA compliance – and OSHA compliance is a good way to ensure you are creating a safe work environment – avoiding OSHA penalties is not the only reason construction leaders should embrace health and safety.

As well as the obvious disruptions and costs, workplace injuries can impact operations in less direct and harder-to-measure ways, such as workplace morale, productivity, and turnover.

AlertMedia found that 81% of workers say physical safety is important to them, but only 58% think it’s important to their employers. By taking control of safety and ensuring that workers feel safe and valued, you can improve recruiting and retention, increase productivity and quality control and enhance your company’s reputation – all of which can sharpen your competitive edge.

We’re here to help.

Construction safety compliance is far more than just a box to tick; it’s the cornerstone of a successful, responsible, and sustainable business operation. It demonstrates your commitment to your most valuable asset – your workforce.

At Watkins Insurance Group, we specialize in providing comprehensive insurance solutions and experience-driven advice tailored to the unique needs of the construction industry. We understand the intricacies of construction risks and can guide you through securing the most suitable coverage for your business.

Connect with us today to enhance your safety compliance and secure the coverage that will protect your business. Together, let’s build a foundation of safety that not only complies with regulations but truly values and protects your workforce.